Wiring Harness Installation is a crucial aspect of any electrical system in a vehicle or machinery. It involves the process of connecting various electrical components together using a wiring harness, which acts as a central hub for all the electrical connections.

Why Wiring Harness Installation is Essential

There are several reasons why Wiring Harness Installation is essential:

- Organizes and secures the wiring in a neat and efficient manner.

- Reduces the risk of electrical shorts or malfunctions due to improper wiring.

- Facilitates easy maintenance and troubleshooting of electrical systems.

- Ensures proper functioning of all electrical components in the vehicle or machinery.

Reading and Interpreting Wiring Harness Installation

When installing a wiring harness, it is important to carefully read and interpret the wiring diagrams provided by the manufacturer. Here are some tips to effectively read and interpret wiring harness installation:

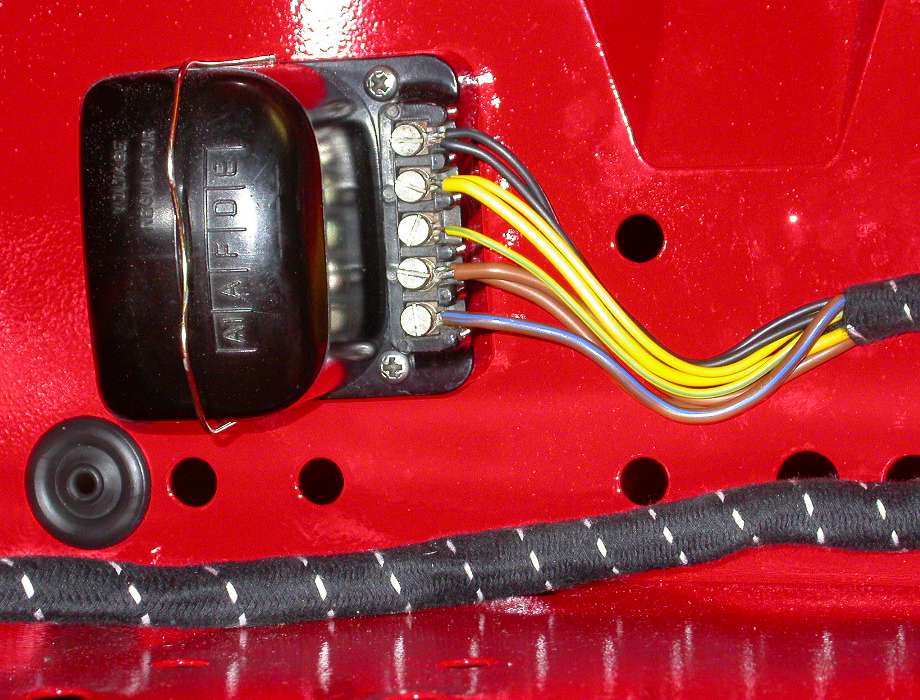

- Start by identifying the main components and their corresponding wiring connections.

- Follow the color codes and markings on the wiring harness to ensure correct connections.

- Refer to the wiring diagram for guidance on the routing of the wiring harness and connection points.

- Double-check all connections before securing the wiring harness in place.

Using Wiring Harness Installation for Troubleshooting

Wiring harness installation can also be used for troubleshooting electrical problems in a vehicle or machinery. By following the wiring harness and checking for continuity, you can easily identify any faulty connections or components. Here are some steps to use wiring harness installation for troubleshooting:

- Check for any loose or disconnected wires in the wiring harness.

- Use a multimeter to test the continuity of the wiring connections.

- Refer to the wiring diagram to identify the source of the electrical problem.

- Replace any damaged or faulty components as needed.

It is important to always prioritize safety when working with electrical systems and using wiring diagrams. Here are some safety tips and best practices to keep in mind:

- Always disconnect the battery before working on any electrical components.

- Use insulated tools to prevent electrical shocks.

- Avoid working on electrical systems in wet or damp conditions.

- Double-check all connections before powering up the electrical system.

Wiring Harness Installation

Step by step wiring harness install – YouTube

Trailer Wiring Harness Install

MGA wiring harness installation

Toyota Tacoma Wiring Harness

Trailer Wiring Harness Diagram – Cadician's Blog

Wiring Harness Diagram For Pioneer Avh 120bt – Wiring Diagram